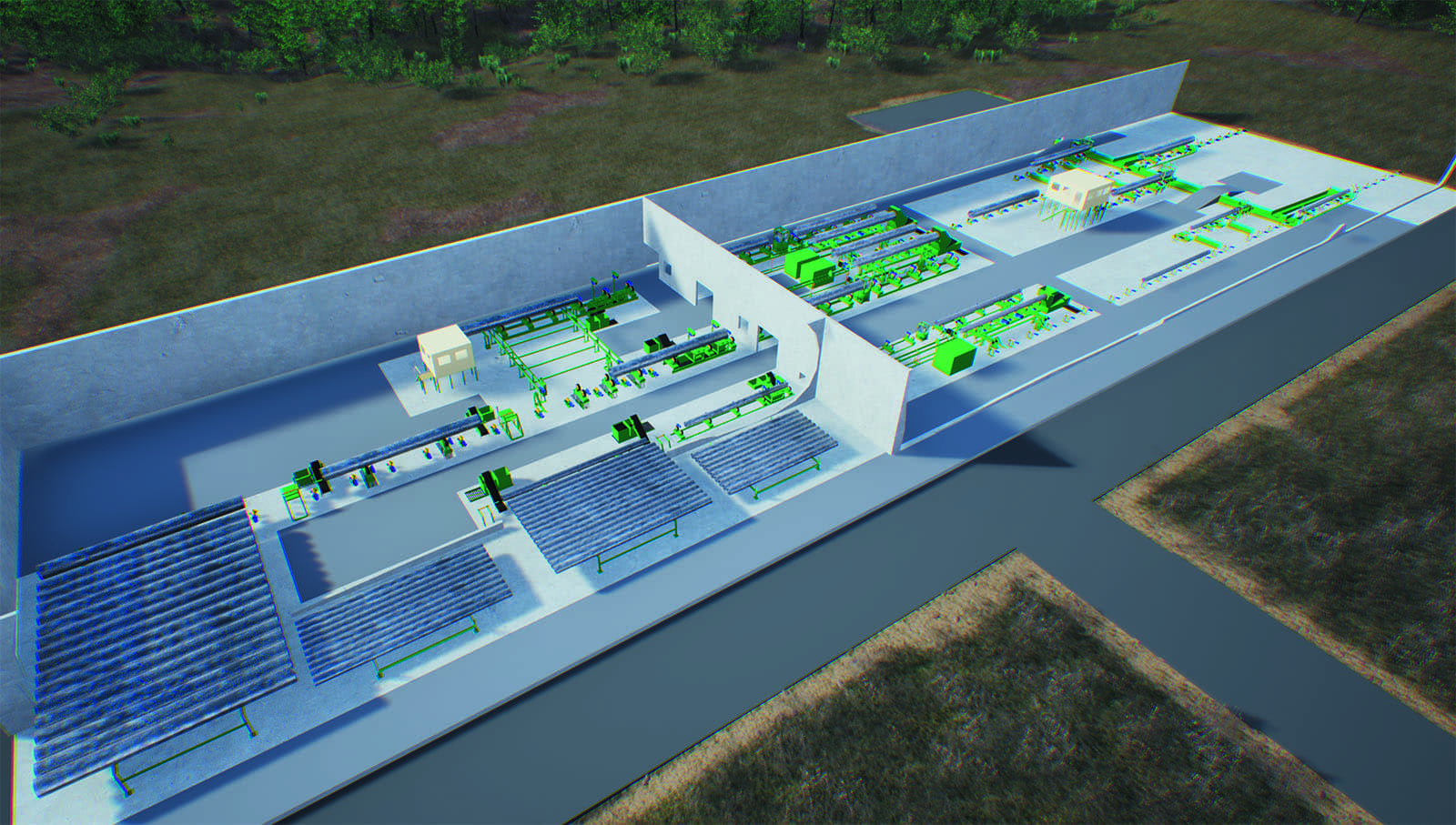

Technological line equipment for limestone recycling, also technological scheme of recycling process, the project of equipment placement and 3D model of the complex were developed by the engineering centre of LLC "Ecotech" in accordance with annual capacity of 2000 thousand tons yearly, with a high level of automation.

Basic technical specifications of the complex.

| Initial material for recycling | Limestone with clay content = 30% |

| Initial fraction | 0-1000 mm |

| Maximum possible fraction | ≤ 1300 mm |

| Moisture | ≤12% |

| Specific weight | 2,4 – 2,6 t\m³ |

| Bulk weight (average value): | 1,67 t\m³ |

| Strength | ≤ 126 MPa |

| Flakiness | ≤ 5% |

| Capacity of the complex | 2000 thousand tons |

| Equipment consumption efficiency coefficient | 0.47 |

| Productivity (required) | 900 t/h |

| Operating parameters of the complex | Open area, t°= -40°C - +40°C |

| Energy supply | Three-phase, 380 V, 50 Hz |

| Enriched fraction | categories | State Standard 8267-93 |

| Final product outlet:

- fraction 5-20 mm - fraction 20-40 mm - fraction 40-70 mm - fraction 70-120 mm |

11% 14% 16% 12% |

| Stock volume of final products | ≥6000 m³ as a percentage of enriched fractions |

Cable-stayed structure is a steel construction, its load-bearing components serve for tension.

LLC "Ecotech" in conjunction with Tula State University have developed, engineered the cable-stayed crossing structure and have calculated its strength. Under condition of restricted space and under special geological conditions it is not always possible to construct crossing/bridge with classic double-sided support structure. Then the cable-stayed structures come to help and allow to apply different constructive forms. They are practically not limited in load-bering capacity, are transporable, easily installed and have few limitations in wind and snow loads. Engineers of LLC "Ecotech" have solved the difficult problem, engineered the cable-stayed crossing to transport limestone from storage area of final products to railway line to load crushed stone into wagons. Transportation volume is up to 7000 tons a day. The cable-stayed structure is a reinforce concrete pylon with anchorage for stays. Stays are attached to the bracing beam, which forms a frame for placement of any equipment. Cable-stayed crossing is constructed above the regional automobile highway, thereby the most advanced safety and automation systems were applied, which allowed to consider all the requirements of supervisory authorities. The installation of cable-stayed crossing is possible to construct without diverting automobile traffic, that is one of the basic requirements of the project. Vertical clearance is 8 meters, and its width - 12 meters.

Learn more..

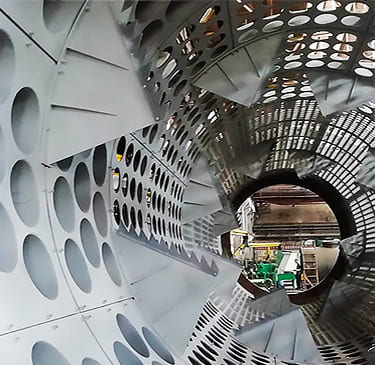

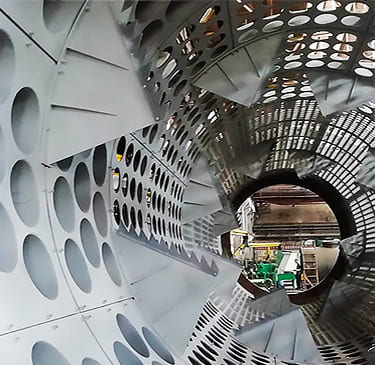

Technological line equipment for gas and oil pipelines cleaning, also technological scheme of recycling process, the project of equipment placement and 3D model of the complex were developed by the engineering centre of LLC "Ecotech" in accordance with annual capacity of 150 thousand tons yearly, with a high level of automation.

Technological line can be devided in 3 phases: Preliminary mechanical pipes cleaning, liquid jet pipes cleaning to the level Sa2, utilization sector and sector of front-end treatment. The sector of automatic troubleshooting by the company MARVIE can be used in the line additionally.

The scheme allows to save consumables (application of water instead of abrasive), pare parts (world leading manufacturers only), to get timely service at minimum cost. The full automation allows to provide the plant operation with 3 lines for pipes cleaning Ø159-Ø1420 with maximum weight 10.000 kg with the personnel of 4 people (2 operators, 2 forklift drivers). The engineering centre of LLC "Ecotech" can complete the lines with equipment of world manufacturers, as well as with domestic analogues with the obligatory modifications, improving the quality and reliability of products.

Learn more..

Technological line equipment for limestone wastes recycling, also technological scheme of recycling process, the project of equipment placement and 3D model of the complex were developed by the engineering centre of LLC "Ecotech" in accordance with annual capacity of 300 thousand tons yearly, with a high level of automation.

List of items included in the complexс